If you’re considering installing an air production system for your business, it is essential to understand how it works. Air compressors can be either fixed speed or variable speed, producing compressed air only when necessary, thus minimizing offload running. This article will provide an overview of how air compressors operate and what you need to know about their different types and applications.

Compressed air

Filter regulator lubricator Charlotte NC, is essential when designing a compressed air production system, the design must consider the amount of pressure variation throughout the system. A secondary storage system is useful to smooth out pressure variations throughout the system. This can be done through the use of storage tanks. DOE’s sourcebook provides more information on secondary storage systems.

This type of system uses advanced software to control the air supply. It can be set to run at full load or operate at partial load. The most efficient compressors should be used in full load mode, while other compressors can be operated at partial load.

Types

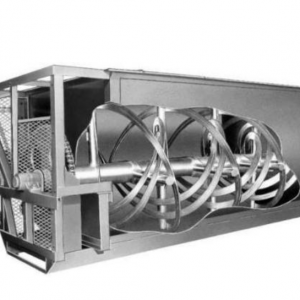

There are many different types of air compressors and air systems. Oil-lubricated or water-lubricated systems are available; some are even designed to produce oil-free air. These systems are designed to meet critical oil-free service demands. These types of air compressors and systems are used in many different applications.

Applications

The applications of air production systems can be found in a wide variety of industries. For example, high-purity air is essential for food and beverage manufacturing and processing. The company can also provide nitrogen generation and storage systems. These systems are designed to minimize waste, maintain constant pressure, and operate at minimum pressure. They can also help save energy by reducing overpressurization. They can also improve the efficiency of compressed air systems.

Inefficiencies

Inefficient air production systems can be costly to maintain. There are several ways to minimize the impact of inefficiencies, including detecting leaks and installing instrumentation to maintain constant air pressure. These steps can minimize the impact of inefficient air on production processes and save you money in the long run. Let’s take a closer look at a few examples. One of the most significant sources of inefficiency is the misuse of compressed air. Some operators consider compressed air a free commodity and devise inventive ways to use it. However, there are several other methods of air products that are much more cost-effective.

Tools

Having the right air tools is a must for any air production system. It is essential to select the right tool for the job since water and other contaminants can damage air tools and reduce their performance. Air tools should have a lubricator and regulator to prevent this from happening. The air supply should also be debris-free, and filters should be regularly changed to keep air tools running at peak efficiency. One of the most common air tools is a pneumatic air tool. These tools use compressed air to operate and run tools. These tools can work in flammable, explosive, and dusty environments. Additionally, they are very easy to maintain.

Maintenance

Performing routine inspections of the air production system is a crucial part of preventative maintenance. This process ensures that the system’s components are in good working order and helps prevent costly system breakdowns and repairs. It also extends the life of the equipment by detecting minor problems early. A well-maintained system will reduce downtime and costs and will increase profitability. However, it requires a significant investment in time and money. Preventive maintenance is essential for compressed air systems. It prevents the buildup of particulates and fluids that can disrupt production processes.